Ace Tips About How Do You Calculate 3ph Amps

Three Phase Voltage Calculations

Understanding 3-Phase Amps

1. Why Bother Calculating 3-Phase Amps?

Okay, so you're staring at a beefy piece of electrical equipment humming away, and you need to know its power demands. Maybe you're sizing a generator, troubleshooting a circuit, or simply trying to avoid accidentally tripping a breaker the size of a small car. Understanding how to calculate 3ph amps is crucial. "3ph amps" (3-phase amps) — here, 'amps' is a noun representing the unit of electrical current — it's the golden ticket to electrical safety and efficiency. It's like knowing how much gas your car needs before embarking on a cross-country road trip. You wouldn't just guess, would you?

Ignoring this crucial step can lead to some seriously unpleasant scenarios. Think flickering lights, overheated wires, and potentially even electrical fires. Nobody wants that kind of excitement in their lives. Besides, having a solid grasp on electrical calculations impresses your friends at parties. Just kidding... mostly.

Whether you're an electrician by trade, a DIY enthusiast tackling a home improvement project, or just someone curious about the inner workings of the electrical world, this guide will break down the process in a way that's easy to understand. We'll ditch the overly complicated jargon and get straight to what you need to know.

Essentially, calculating 3ph amps is all about ensuring you have enough "electrical juice" to power your equipment safely and reliably. It's about matching the demand with the supply, like finding the perfect dance partner. Mismatched partners lead to awkwardness; mismatched electrical systems lead to well, sparks.

The Formula

2. The Core Equation

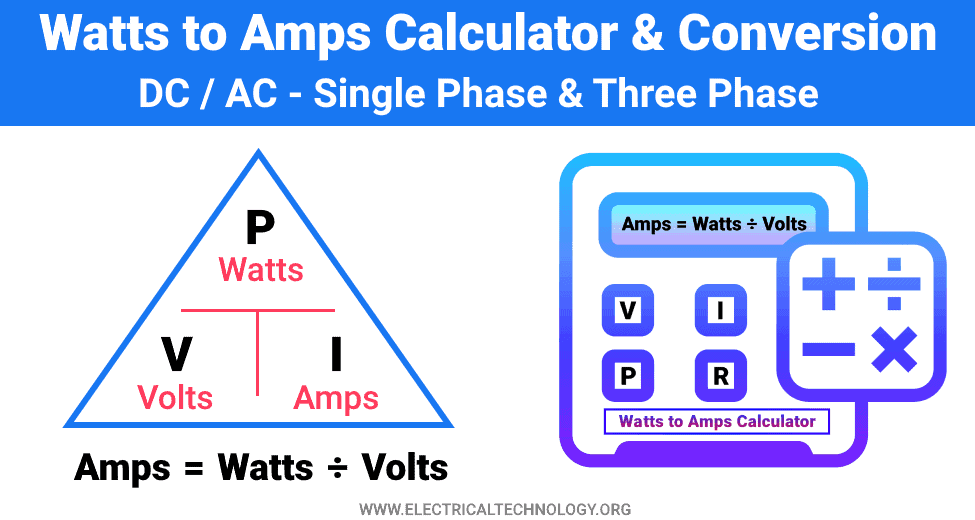

Alright, let's get down to brass tacks. The magic formula you'll need to calculate 3ph amps depends on whether you're dealing with horsepower (HP) or kilowatts (kW). Don't worry, we'll cover both!

For horsepower: Amps = (HP x 746) / (Volts x √3 x Efficiency x Power Factor)

And for kilowatts: Amps = (kW x 1000) / (Volts x √3 x Power Factor)

Hold on, don't run away screaming just yet! Let's break down each of these terms. "Volts" is the voltage of the circuit (usually 208, 230, 460, or 480 volts). "√3" is the square root of 3, which is approximately 1.732 (a constant used in 3-phase calculations). "Efficiency" is the efficiency of the motor, expressed as a decimal (e.g., 0.85 for 85% efficiency). "Power Factor" is a measure of how effectively the electrical power is being used, also expressed as a decimal (typically between 0.8 and 0.95). It's like the engine's ability to turn fuel to power.

Think of this formula as a recipe. Each ingredient (HP, Volts, etc.) contributes to the final product: the amps! Without understanding the recipe, you'll just end up with a mess. And in the world of electricity, a mess can be quite shocking (pun intended).

Amps Law Calculator At Susan Pietsch Blog

Example Time

3. Calculating Amps for a Motor

Let's say you have a 10 HP motor running on a 480-volt 3-phase system. The motor has an efficiency of 85% (0.85) and a power factor of 0.9. Let's plug those numbers into our formula:

Amps = (10 HP x 746) / (480 Volts x √3 x 0.85 x 0.9)

Amps = 7460 / (480 x 1.732 x 0.85 x 0.9)

Amps = 7460 / 637.45

Amps ≈ 11.7 Amps

Therefore, this 10 HP motor will draw approximately 11.7 amps. Now you know how to size the appropriate circuit breaker and wiring to handle the load safely!

Remember, this is just an example. The specific values for HP, Volts, Efficiency, and Power Factor will vary depending on the equipment you're working with. Always consult the equipment's nameplate for accurate information.

Factors Affecting Amp Draw

4. Things to Consider

While the formula provides a solid foundation, several factors can influence the actual amp draw of a 3-phase system. It's like baking a cake — even with a perfect recipe, humidity, oven temperature, and even the quality of your ingredients can affect the final outcome.

One crucial factor is the load. A motor under heavy load will draw more amps than a motor running idle. Think of it like driving a car uphill versus downhill — you'll need more gas (and thus, more power) to climb the hill.

Another factor is voltage fluctuations. If the voltage drops below the specified level, the equipment will draw more amps to compensate. It's like trying to pump water through a narrow pipe — you'll need more pressure to get the same flow.

Harmonic distortion, often caused by non-linear loads like variable frequency drives (VFDs), can also increase amp draw. These harmonics add extra "noise" to the electrical signal, increasing the overall current flow. It's like adding extra, unnecessary instruments to an orchestra — it just makes everything louder and more chaotic.

Environmental conditions like temperature can also play a role. Hotter temperatures can increase the resistance of conductors, leading to higher amp draw. Think of it like trying to run a marathon in the desert — your body will work harder and require more energy.

Troubleshooting

5. What to Do When Amps Are Too High

So, you've calculated the expected amp draw, but your ammeter is showing a significantly higher reading. Don't panic! This could indicate a problem with the equipment or the electrical system. It's like your car is overheating after an oil change — something is definitely amiss.

First, check the equipment for any signs of damage or malfunction. Listen for unusual noises, look for overheating, and smell for burning odors. A visual inspection can often reveal obvious problems.

Next, verify the voltage and power factor. Low voltage or a poor power factor can increase amp draw. Correcting these issues can often resolve the problem. Imagine you are trying to blow up a balloon and there are some holes in the balloon, the air is going out. You will have to provide more air to inflate it.

If you suspect harmonic distortion, consider using a harmonic analyzer to measure the levels of harmonics in the system. Installing harmonic filters can help reduce distortion and lower amp draw.

Finally, if all else fails, consult a qualified electrician. Electrical troubleshooting can be dangerous, and it's always best to leave complex issues to the professionals. It's like attempting brain surgery with a butter knife — it's probably not a good idea.