Simple Info About Is 12 AWG Thicker Than 10

Is 12 AWG Thicker Than 10 AWG? Let's Untangle This Wire Mess!

1. Understanding Wire Gauge

Okay, let's face it. Wire gauge sizes can be a bit of a head-scratcher. It feels counterintuitive, doesn't it? Like, why would a bigger number mean a smaller wire? It's one of those quirks of electrical work that just takes a little getting used to. So, if you're staring at two spools of wire — one labeled "12 AWG" and the other "10 AWG" — and wondering which one is the beefier brother, you're not alone.

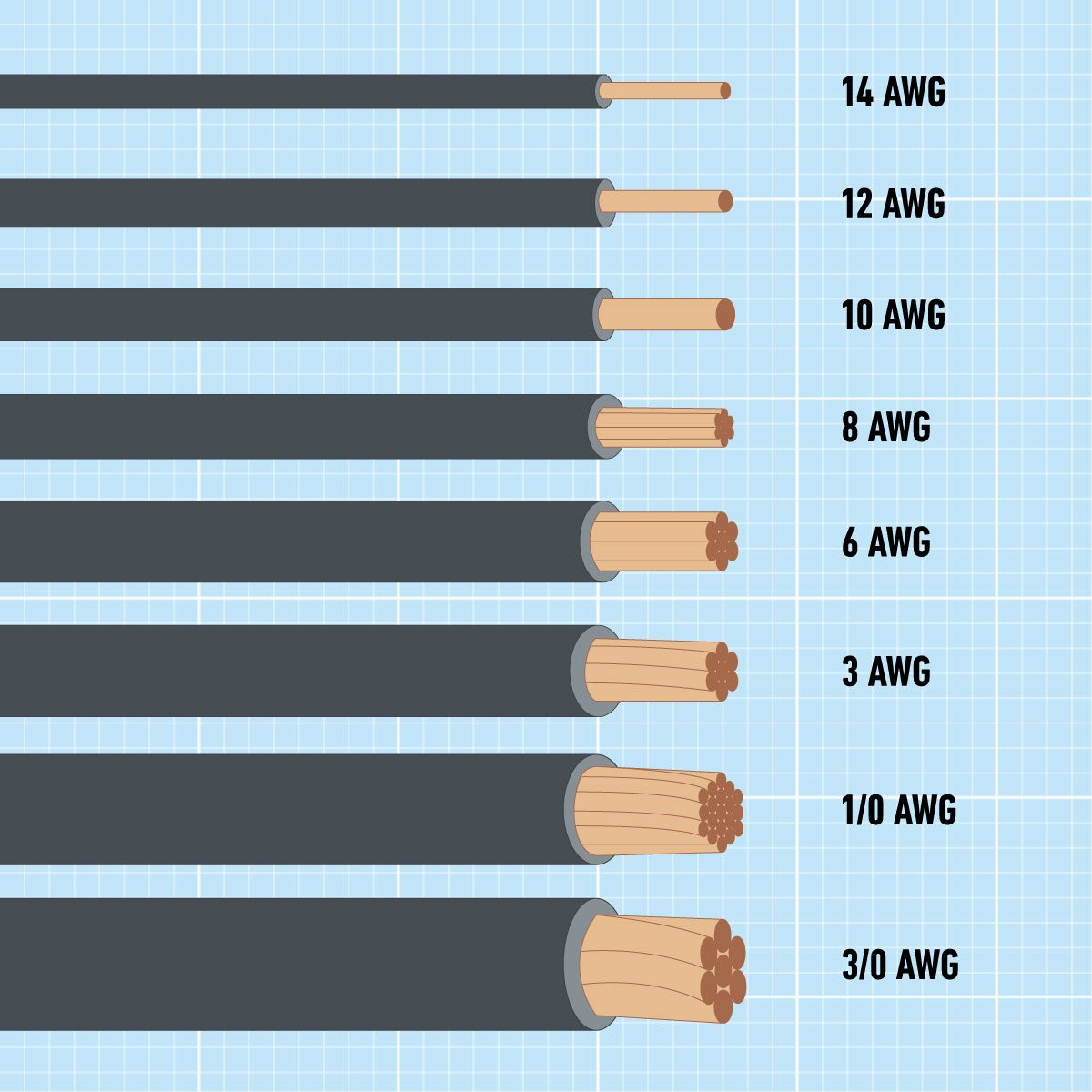

The key takeaway here is that the AWG (American Wire Gauge) system is inversely proportional to the wire's thickness. Think of it like shoe sizes— a size 12 shoe is generally larger than a size 10. But with wire gauges, a smaller number indicates a larger diameter. So, a 10 AWG wire is physically thicker than a 12 AWG wire. Easy peasy, right?

This thickness difference is crucial because it directly impacts how much current the wire can safely carry. Thicker wires, like the 10 AWG, have less resistance, allowing more electricity to flow without overheating. Using a wire that's too thin for the current load is a recipe for disaster — think melted insulation and potential fire hazards. Not exactly a fun weekend project!

Therefore, remember this simple rule: lower AWG number, bigger wire, higher current capacity. Keep this in mind and you'll avoid any electrifying surprises! (Pun intended, of course.)

Delving Deeper

2. Decoding the Mystery

So, where does this strange numbering system come from? The American Wire Gauge is based on the number of drawing operations required to produce a particular wire size. Imagine taking a thick piece of metal and pulling it through progressively smaller dies. Each draw makes the wire thinner and longer.

A 0 AWG wire (also written as 1/0, 2/0, 3/0, 4/0 for even larger sizes) is quite substantial, needing fewer drawing operations to reach that diameter. A much smaller wire, like a 30 AWG, requires significantly more drawing steps to achieve its tiny size. This process gave rise to the AWG numbering system we know today. It wasn't created based on the wire size directly.

Understanding the origin of AWG helps to remember the inverse relationship. The more "work" (drawing operations) done on the wire, the higher the AWG number and the smaller the resulting wire diameter.

Ultimately, whether you're wiring a new outlet, working on an automotive project, or just curious about how electricity flows, knowing the basics of AWG can save you time, money, and possibly even a trip to the emergency room. So, take note of it.

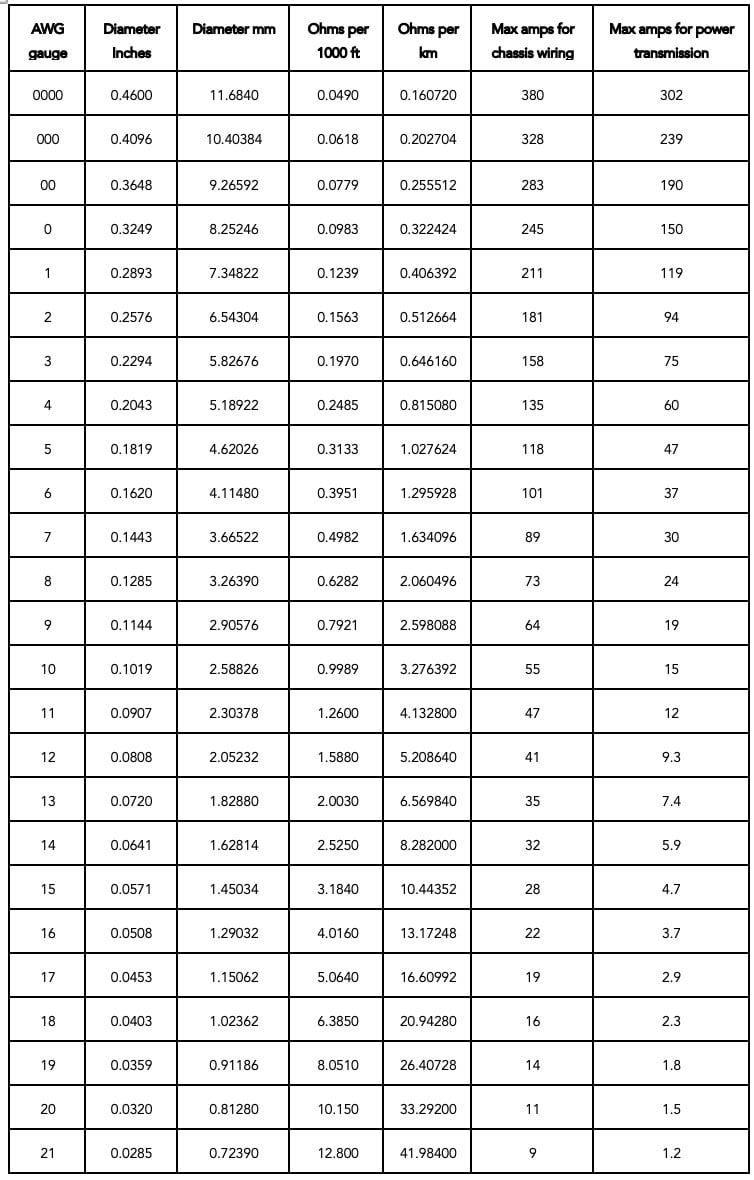

Tabla "AWG" De Calibres Alambre Estadounidensestabla Tamaño Y

Why Does Wire Thickness Matter? The Current Carrying Capacity

3. Ampacity

The primary reason wire thickness matters is its ampacity, which refers to the maximum amount of electrical current a conductor can carry before it risks damage or overheating. A thicker wire, like 10 AWG, has a lower resistance to current flow. This means that for a given amount of current, less heat will be generated within the wire itself.

Think of it like water flowing through a pipe. A wider pipe allows more water to flow with less pressure, while a narrower pipe restricts the flow and increases the pressure. Similarly, a thicker wire allows more current to flow with less resistance, preventing the wire from getting dangerously hot.

Using a wire with insufficient ampacity is a serious safety hazard. Overheating can melt the wire's insulation, potentially causing short circuits, fires, and electrical shocks. It's crucial to consult electrical codes and guidelines to determine the appropriate wire gauge for your specific application, considering the current load and the length of the wire run.

Always err on the side of caution when choosing wire gauges. It's better to use a slightly thicker wire than a slightly thinner one, as the cost difference is minimal compared to the potential consequences of an electrical failure.

12 AWG vs. 10 AWG

4. Where Each Wire Shines

Now that we know 10 AWG is thicker, where would you typically use each type of wire? Generally, 12 AWG wire is commonly used for 20-amp circuits, such as those powering kitchen appliances, outlets in living rooms, and other general-purpose applications. It's a versatile wire that strikes a good balance between current-carrying capacity and ease of handling.

10 AWG wire, on the other hand, is typically used for 30-amp circuits. Common applications include electric dryers, water heaters, and air conditioning units. These appliances draw more current than typical household circuits, requiring a thicker wire to handle the load safely and prevent overheating.

When deciding between 12 AWG and 10 AWG, consider the amperage of the circuit and the devices that will be connected to it. Check the appliance's nameplate for its current requirements and consult local electrical codes to ensure you're using the appropriate wire gauge. For example, most household circuits using 20 amps will likely use 12 AWG.

Remember, the right wire gauge is not just about functionality; it's about safety. Always prioritize safety when working with electricity, and if you're unsure about anything, consult a qualified electrician.

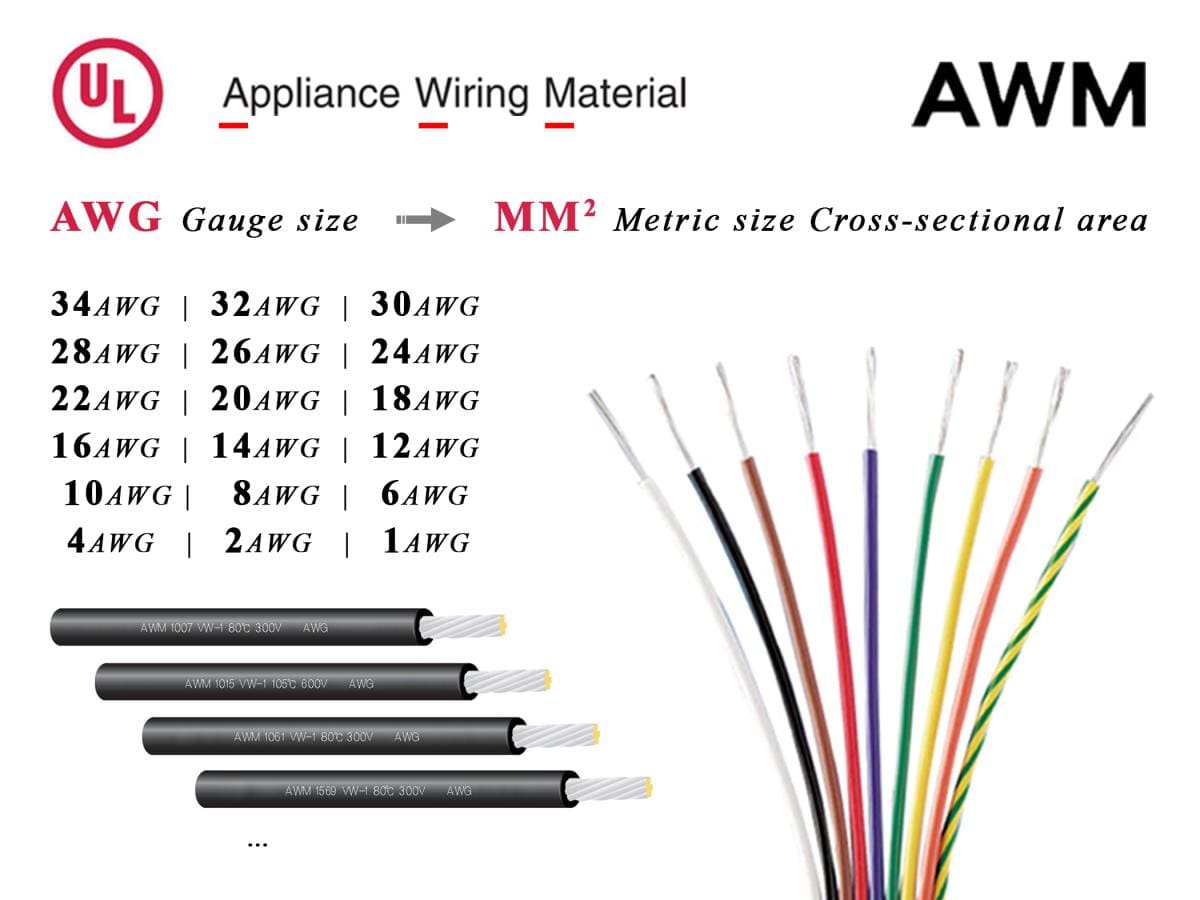

Dây Cáp điện AWM UL Bảng Chuyển đổi đơn Vị AWG Sang MM2

Practical Tips for Working with Wire

5. Wiring Wisdom

Working with electrical wire doesn't have to be intimidating. With the right tools and a little knowledge, you can tackle many electrical projects safely and confidently. First, always turn off the power at the circuit breaker before working on any electrical wiring. This is non-negotiable. Double-check that the power is off with a non-contact voltage tester before proceeding.

Use appropriate wire strippers to remove the insulation from the wire without damaging the conductor. Damaged conductors can lead to hotspots and potential electrical failures. Make sure you're using the correct size setting on your wire strippers for the wire gauge you're working with.

When making connections, ensure they are tight and secure. Loose connections can cause arcing and overheating. Use wire connectors or terminal screws to create solid, reliable connections. A properly made connection should feel firm and not wiggle easily.

Finally, always follow local electrical codes and regulations. These codes are in place to protect you and your property from electrical hazards. If you're unsure about any aspect of electrical work, don't hesitate to consult a qualified electrician. They can provide expert advice and ensure that your electrical system is safe and up to code.